Hand Assembly Flexibility

In today’s world you would expect most products to be packed by machines. There are many reasons why this does not happen but the largest is cost. If there is not a Return on Investment “ROI” to purchase a machine, then hand packing is normally involved. If you need the flexibility to change multiple sizes or short run packs. If it’s an awkward shape or unbalanced or simply too large or heavy. People are our most flexible resource and we have up to 200 trained!

Kit Assembly

We can pack kits in any way you want. The largest one we process today is more than 400 parts, is made up of many smaller sub kits and is packed sequentially in order into a large wooden presentation case. The most important requirement of packing any kit is to ensure the parts all there! We have considerable experience in kitting and can perform checks by weight and visually with digital inspection if required.

Clean Room Booth

This is for Engineering components where particles in the air cannot be introduced to a part that can contribute to failure and abnormal wear. This is typically used in parts that have very fine operating tolerances. It is a secure, sealed area that has its own air filtration system.

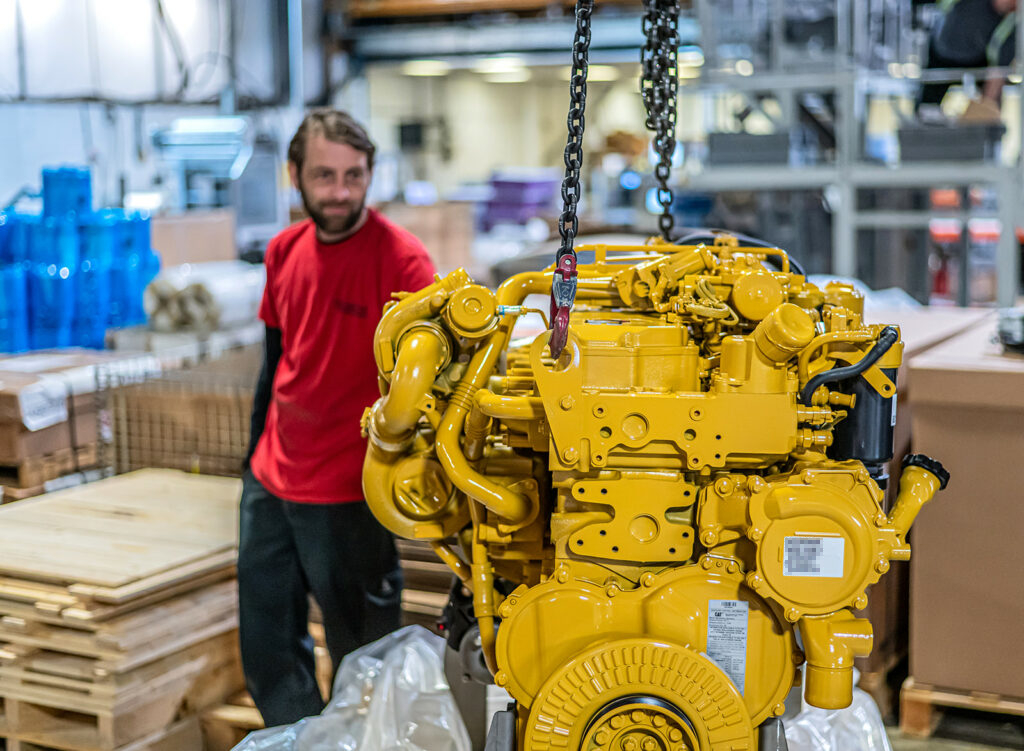

Heavy Packing

Onward shipment of large and heavy components often requires additional packaging such as support frames and cases, these ensure the products safety and security. We also add additional components, riveted serial plates and statutory markings and documents when required

Why do we hand pack?

Hand packing with people provides enormous flexibility on what can be packed. It provides flexibility over pack runs, sizes, weights in fact pretty much everything. To achieve a return on a machine for the work it will perform requires significant run sizes that are normally achieved at the end of a production lines and it will still require space, electric and staff to maintain and operate.

Other Packing Services

- Quality Inspection – Services provided to your requirements

- Rectification – Reworking parts that may have failed inspection

- Core Review and Sorting – For components return exchanges

- Case assembly – For heavy parts by air and sea freight

Please Contact Us

Please contact us, we will be pleased to discuss your individual requirements

Get In Touch